female and female 90° long sweep bend

Products Detail

Category150 Class BS / EN standard Beaded Malleable cast iron pipe fittings

- Certificate: UL Listed / FM Approved

- Surface: Black iron / hot dip galvanized

- End: Beaded

- Brand: P and OEM is acceptable

- Standard: ISO49/ EN 10242, symbol C

- Material: BS EN 1562, EN-GJMB-350-10

- Thread: BSPT / NPT

- W. pressure: 20 ~ 25 bar, ≤PN25

- Tensile Strength: 300 MPA(Minimum)

- Elongation:6% Minimum

- Zinc Coating: Average 70 um, each fitting ≥63 um

Available Size:

| Item |

Size |

Weight |

| Number |

(Inch) |

KG |

| EBL9005 |

1/2 |

0.13 |

| EBL9007 |

3/4 |

0.253 |

| EBL9010 |

1 |

0.374 |

| EBL9012 |

1.1/4 |

0.656 |

| EBL9015 |

1.1/2 |

0.848 |

Our Advantages

1.Heavy molds and competitive prices

2.Having accumulating Experience on producing and exporting since 1990s

3.Efficient Service: Replying a Inquiry within 4 hours, fast delivery.

4. Third party certificate, such as UL and FM, SGS.

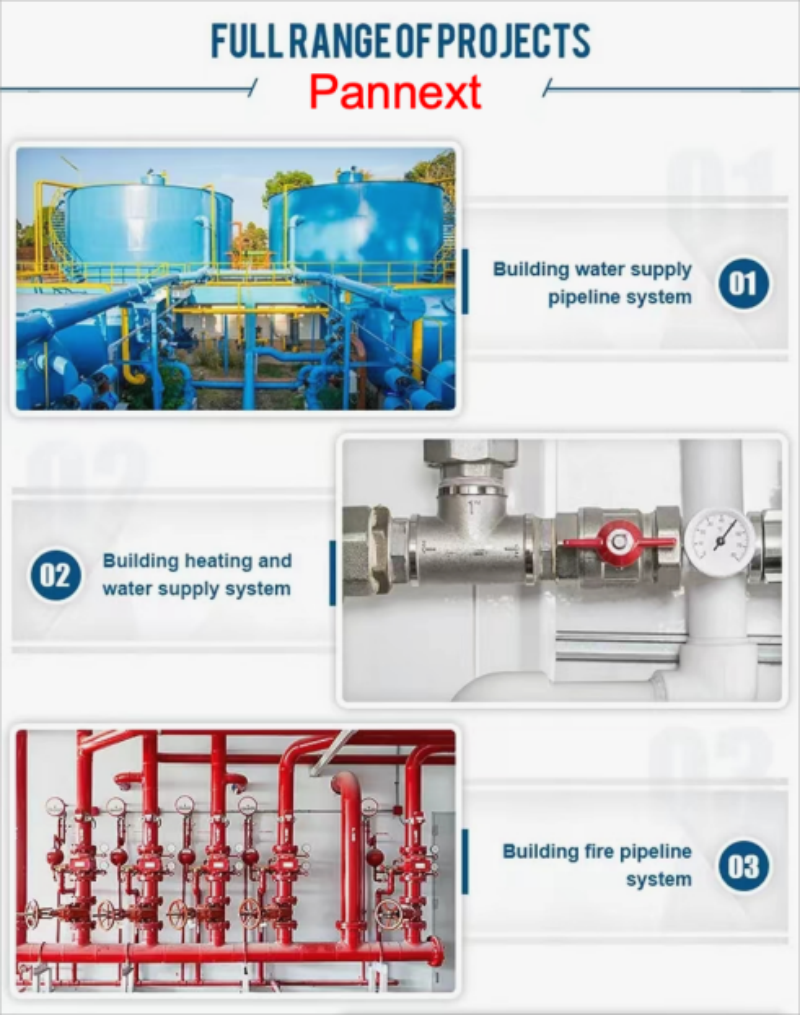

Applications

Our Slogan

Keep every pipe fitting that our Clients’ received is qualified.

FAQ

1.Q:Are you factory or trading company?

A:We are factory with +30 years history in casting field.

2.Q: What terms of payment do you support?

A: TTor L/C. 30% payment in advance, and the 70%balance would be paid before shipment.

3.Q: How long is your delivery time?

A: 35 days upon receipt of advanced payment.

4.Q: Your Package?

A.Exporting Standard. 5-layer Master Cartons with inner boxes, Generally 48 Cartons packed in on pallet, and 20 pallets loaded in 1 x 20”container.

5. Q: lt is possible to get samples from your factory?

A: Yes. free samples will be provided.

6. Q: How many years the products guaranteed?

A: Minimum 1 years.

7.Types of pipe fitting standards:

Some widely used pipe fitting standards are as follows:

ASME: American Society for Mechanical Engineers

This is one of the reputed organizations in the world developing codes and standards. The schedule number for pipe fitting starts from ASME/ANSI B16. The various classifications of ASME/ANSI B16 standards for different pipe fittings are as follows:

- ASME/ANSI B16.1 - 1998 - Cast Iron Pipe Flanges and Flanged Fittings

- ASME/ANSI B16.3 - 1998 - Malleable Iron Threaded Fittings

- ASME/ANSI B16.4 - 1998 - Cast Iron Threaded Fittings

- ASME/ANSI B16.5 - 1996 - Pipe Flanges and Flanged Fittings

- ASME/ANSI B16.11 - 2001 - Forged Steel Fittings, Socket-Welding and Threaded

- ASME/ANSI B16.14 - 1991 - Ferrous Pipe Plugs, Bushings and Locknuts with Pipe Threads

- ASME/ANSI B16.15 - 1985 (R1994) - Cast Bronze Threaded Fittings

- ASME/ANSI B16.25 - 1997 - Buttwelding Ends

- ASME/ANSI B16.36 - 1996 - Orifice Flanges etc.