Half Threaded Socket or Coupling UL Certificate

Products Detail

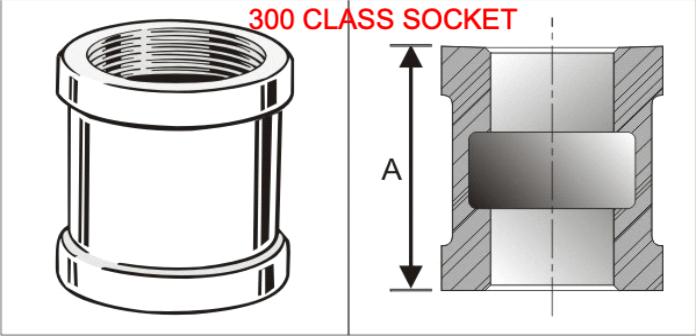

American standard malleable iron pipe fittings, category 300

Certificate: FM and UL Listed Approved

Surface: Hot-dip galvanized and black iron

Material: malleable iron Standard: ASME B16.3 ASTM A197

pressure: 300 PSI, 10 kg/cm at 550°F, thread: NPT/BS21 W

Surface: Hot-dip galvanized and black iron

Strength in Tension: 28.4 kg/mm (Minimum)

Elongation:5% Minimum

Zinc Coating: Each fitting 77.6 um and averaging 86 um.

Available Size:

|

Item |

Size (inch) |

Dimensions |

Case Qty |

Special Case |

Weight |

|||||||||||||||

|

Number |

|

|

A |

|

B |

Master |

Inner |

Master |

Inner |

(Gram) |

||||||||||

| CPL02 | 1/4 |

|

34.8 |

400 |

200 |

200 |

100 |

68 |

||||||||||||

| CPL03 | 3/8 |

|

41.4 |

240 |

120 |

150 |

75 |

111 |

||||||||||||

| CPL05 | 1/2 | 47.5 |

80 |

40 |

40 |

20 |

181 |

|||||||||||||

| CPL07 | 3/4 | 53.8 |

60 |

30 |

30 |

15 |

279 |

|||||||||||||

| CPL10 | 1 | 60.2 |

40 |

20 |

20 |

10 |

416.5 |

|||||||||||||

| CPL12 | 1-1/4 | 72.9 |

24 |

12 |

12 |

6 |

671.7 |

|||||||||||||

| CPL15 | 1-1/2 | 72.9 |

24 |

12 |

12 |

6 |

835 |

|||||||||||||

| CPL20 | 2 | 91.9 |

12 |

6 |

6 |

3 |

1394 |

|||||||||||||

| CPL25 | 2-1/2 | 104.6 |

4 |

2 |

2 |

2 |

2216 |

|||||||||||||

| CPL30 | 3 | 104.6 |

4 |

2 |

2 |

2 |

3204 |

|||||||||||||

| CPL40 | 4 | 108.0 |

4 |

2 |

2 |

1 |

4700 |

|||||||||||||

Applications

Application

This fitting is mainly used to connect different types of pipes, such as water pipes, gas pipes, and oil pipes. It is typically used in construction, chemical, agricultural, mining, and manufacturing industries, among others. It is able to withstand high temperatures and pressures, making it widely used in some important industrial applications.

Features

- Malleability: This fitting is made of malleable cast iron and can be deformed during hot processing, making it suitable for many different applications. The malleability also allows the product to better accommodate pipe deformations and vibrations.

- Durability: Malleable cast iron has high strength and corrosion resistance, making it able to be used for long periods of time without damage. This durability makes it the preferred choice for many applications.

- Easy installation: The design of this fitting makes it very easy to install and remove as it only requires rotation to connect with other fittings, without the need for any tools.

- Universality: This product conforms to American standards and is therefore compatible with other fittings that conform to those standards. This makes the product very versatile and able to be used in various pipe systems.

The "300 Class American Standard Malleable Iron Pipe Fittings Socket/Coupling" is a powerful, durable, and easy-to-install fitting. It is widely used in construction, chemical, agricultural, mining, and manufacturing industries due to its malleability, durability, easy installation, and universality.

Our Slogan

Keep every pipe fitting that our Clients’ received is qualified.

FAQ

Q:Are you factory or trading company?

A:We are factory with +30 years history in casting field.

Q: What terms of payment do you support?

A: TTor L/C. 30% payment in advance, and the 70%balance would be paid before shipment.

Q: How long is your delivery time?

A: 35 days upon receipt of advanced payment.

Q: lt is possible to get samples from your factory?

A: Yes. free samples will be provided.

Q: How many years the products guaranteed?

A: Minimum 1 years.