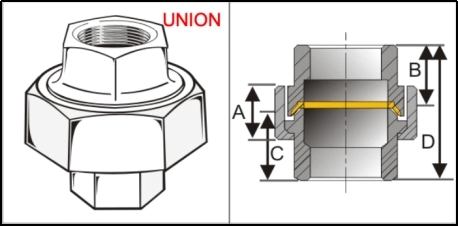

Union with Brass Seat Threading Fitting

Products Detail

Category 300 Class American standard Malleable iron pipe fittings

- Certificate: UL Listed / FM Approved

- Surface: Black iron / Hot dip galvanized

- Standard: ASME B16.3

- Material: Malleable iron ASTM A197

- Thread: NPT / BS21

- W. pressure: 300 P.S.I. 10 kg/cm at 550° F

- Surface: Black iron / Hot dip galvanized

- Tensile Strength:28.4 kg/mm(Minimum)

- Elongation:5% Minimum

- Zinc Coating: Average 86 um, each fitting≥77.6 um

Available Size:

|

Item |

Size (inch) |

Dimensions |

Case Qty |

Special Case |

Weight |

|||||

|

Number |

A | B | C | D |

Master |

Inner |

Master |

Inner |

(Gram) |

|

| H-UNI02 | 1/4 | 19.5 | 17.5 | 22.0 |

200 |

50 |

100 |

50 |

130.5 |

|

| H-UNI03 | 3/8 | 22.5 | 19.0 | 24.2 |

120 |

60 |

90 |

45 |

233 |

|

| H-UNI05 | 1/2 | 24.5 | 20.0 | 27.0 |

80 |

40 |

40 |

20 |

261.4 |

|

| H-UNI07 | 3/4 | 27.5 | 21.0 | 29.0 |

60 |

30 |

30 |

15 |

400 |

|

| H-UNI10 | 1 | 29.0 | 23.0 | 32.5 |

36 |

18 |

18 |

9 |

665.8 |

|

| H-UNI12 | 1-1/4 | 33.0 | 26.0 | 38.0 |

24 |

12 |

12 |

6 |

945.8 |

|

| H-UNI15 | 1-1/2 | 35.5 | 29.0 | 41.5 |

20 |

10 |

10 |

5 |

1121.3 |

|

| H-UNI20 | 2 | 42.0 | 32.0 | 45.0 |

12 |

6 |

6 |

3 |

1914 |

|

| H-UNI25 | 2-1/2 | 44.0 | 37.0 | 51.0 |

8 |

4 |

4 |

2 |

2347 |

|

| H-UNI30 | 3 | 55.5 | 43.0 | 58.0 |

6 |

2 |

3 |

1 |

3582.5 |

|

| H-UNI40 | 4 | 61.5 | 54.0 | 64.5 |

2 |

1 |

1 |

1 |

8450 |

|

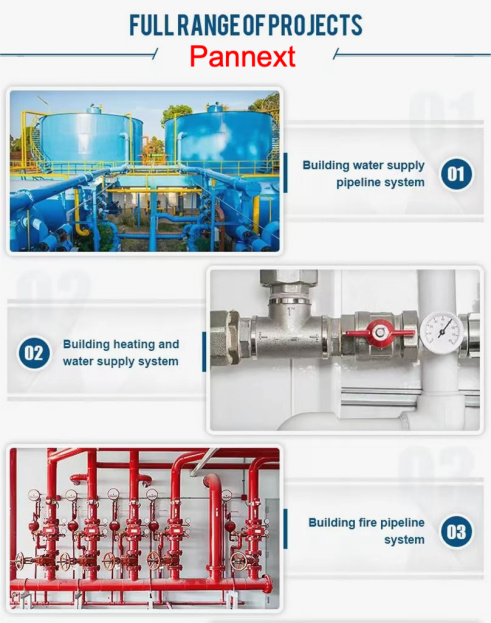

Applications

1.Building water supply pipeline system

2.Building heating and water supply system

3.Building fire pipeline system

4.Building gas pipeline system

5.Oil pipeline piping system

6.Other non corrosive liquid I gas pipelines

Features

The 300 Class American Standard Malleable Iron Pipe Fittings Union With Brass Seat is a detachable fitting with both female threaded connections, featuring a ball-to-cone or ball-to-ball joint. It consists of a male tail, a female head, a union nut, and a brass seat, delivering strong performance and various functions.

Firstly, this malleable iron union is suitable for pipeline connections in many industries, including industrial, chemical, petroleum, natural gas, aerospace, shipbuilding, construction, and water treatment. Whether under high pressure or low pressure, this union can provide a reliable connection, ensuring the smooth flow of fluids in pipelines.

Secondly, this product is characterized by its corrosion resistance and durability. Made of malleable iron and treated with heat and galvanizing, it can prevent corrosion and rust in different environments. Moreover, the brass seat enhances the sealing performance of the union, ensuring good performance even under high temperature, high pressure, and vibration.

In addition, this product is easy to install and disassemble, thanks to the ball-to-cone or ball-to-ball joint connection. The union nut is made of high-quality steel, sturdy and reliable, and can be adjusted according to the needs of different pipelines.

Finally, this product meets American and international standards, ensuring high interchangeability and compatibility. Customers can purchase and use it with confidence, and also enjoy excellent after-sales service.

In summary, the 300 Class American Standard Malleable Iron Pipe Fittings Union With Brass Seat is a strong and versatile pipeline connection fitting, suitable for various industries and applications.

Our Slogan

Keep every pipe fitting that our Clients’ received is qualified.

FAQ

Q:Are you factory or trading company?

A:We are factory with +30 years history in casting field.

Q: What terms of payment do you support?

A: TTor L/C. 30% payment in advance, and the 70%balance would be paid before shipment.

Q: How long is your delivery time?

A: 35 days upon receipt of advanced payment.

Q: lt is possible to get samples from your factory?

A: Yes. free samples will be provided.

Q: How many years the products guaranteed?

A: Minimum 1 years.