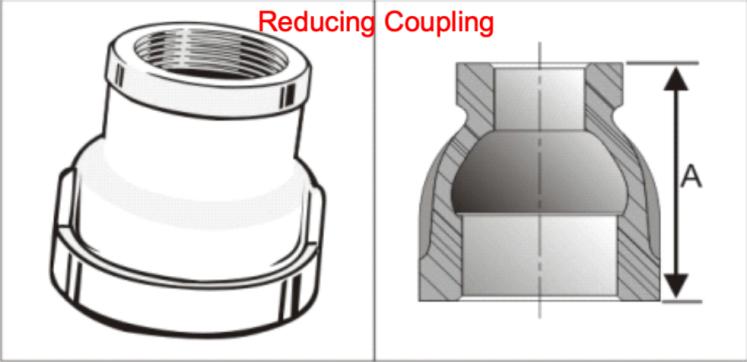

Reducing Socket or Coupling 300 Class

Products Detail

Category 300 Class American standard Malleable iron pipe fittings

- Certificate: UL Listed / FM Approved

- Surface: Black iron / Hot dip galvanized

- Standard: ASME B16.3

- Material: Malleable iron ASTM A197

- Thread: NPT / BS21

- W. pressure: 300 P.S.I. 10 kg/cm at 550° F

- Surface: Black iron / Hot dip galvanized

- Tensile Strength:28.4 kg/mm(Minimum)

- Elongation:5% Minimum

- Zinc Coating: Average 86 um, each fittings ≥77.6 um

Available Size:

|

Item |

Size (inch) |

Dimensions |

Case Qty |

Special Case |

Weight |

|||||

|

Number |

A | B | C | D |

Master |

Inner |

Master |

Inner |

(Gram) |

|

| RCP0302 | 3/8 X 1/4 | 36.6 |

240 |

120 |

120 |

60 |

94 |

|||

| RCP0502 | 1/2 X 1/4 | 42.9 |

200 |

100 |

100 |

50 |

127 |

|||

| RCP0503 | 1/2 X 3/8 | 42.9 |

200 |

100 |

120 |

60 |

137 |

|||

| RCP0702 | 3/4 X 1/4 | 44.5 |

120 |

60 |

120 |

60 |

200 |

|||

| RCP0703 | 3/4 X 3/8 | 44.5 |

120 |

60 |

120 |

60 |

187.5 |

|||

| RCP0705 | 3/4 X 1/2 | 44.5 |

120 |

60 |

60 |

30 |

211 |

|||

| RCP1005 | 1 X 1/2 | 50.8 |

90 |

45 |

50 |

25 |

305.3 |

|||

| RCP1007 | 1 X 3/4 | 50.8 |

80 |

40 |

40 |

20 |

328.2 |

|||

| RCP1205 | 1-1/4 X 1/2 | 60.5 |

40 |

20 |

20 |

10 |

467 |

|||

| RCP1207 | 1-1/4 X 3/4 | 60.5 |

40 |

20 |

20 |

10 |

492 |

|||

| RCP1210 | 1-1/4 X 1 | 60.5 |

40 |

20 |

20 |

10 |

551 |

|||

| RCP1505 | 1-1/2 X 1/2 | 68.3 |

36 |

18 |

18 |

9 |

611.7 |

|||

| RCP1507 | 1-1/2 X 3/4 | 68.3 |

36 |

18 |

18 |

9 |

637 |

|||

| RCP1510 | 1-1/2 X 1 | 68.3 |

36 |

18 |

18 |

9 |

675 |

|||

| RCP1512 | 1-1/2 X 1-1/4 | 68.3 |

36 |

18 |

18 |

9 |

753 |

|||

| RCP2005 | 2 X 1/2 | 81.0 |

16 |

8 |

8 |

2 |

981.3 |

|||

| RCP2007 | 2 X 3/4 | 81.0 |

24 |

12 |

12 |

6 |

1017 |

|||

| RCP2010 | 2 X 1 | 81.0 |

24 |

12 |

12 |

6 |

1008 |

|||

| RCP2012 | 2 X 1-1/4 | 81.0 |

16 |

8 |

8 |

4 |

1101.3 |

|||

| RCP2015 | 2 X 1-1/2 | 81.0 |

16 |

8 |

8 |

4 |

1139 |

|||

| RCP2515 | 2-1/2 X 1-1/2 | 93.7 |

8 |

4 |

4 |

2 |

1704 |

|||

| RCP2520 | 2-1/2 X 2 | 93.7 |

12 |

6 |

6 |

3 |

1767.5 |

|||

| RCP3020 | 3 X 2 | 103.1 |

8 |

4 |

4 |

2 |

2818 |

|||

| RCP3025 | 3 X 2-1/2 | 103.1 |

8 |

4 |

4 |

2 |

3008 |

|||

| RCP3525 | 3-1/2 X 2-1/2 |

6 |

3 |

3 |

1 |

|||||

| RCP4030 | 4 X 3 | 112.0 |

4 |

2 |

2 |

1 |

4008 |

|||

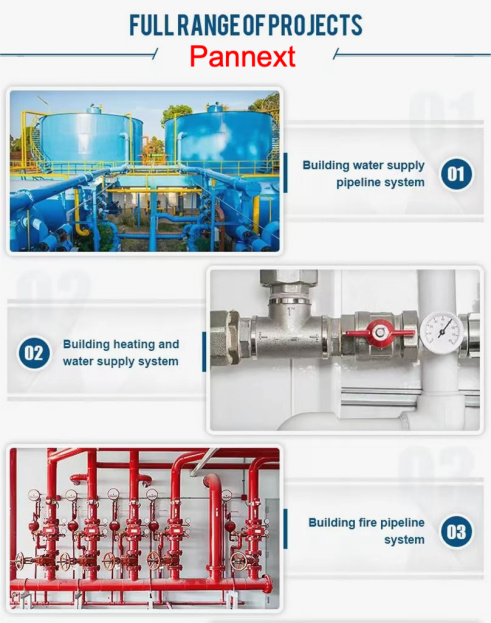

Applications

1.Building water supply pipeline system

2.Building heating and water supply system

3.Building fire pipeline system

4.Building gas pipeline system

5.Oil pipeline piping system

6.Other non corrosive liquid I gas pipelines

Our Slogan

Keep every pipe fitting that our Clients’ received is qualified.

FAQ

1.Q:Are you factory or trading company?

A:We are factory with +30 years history in casting field.

2.Q: What terms of payment do you support?

A: TTor L/C. 30% payment in advance, and the 70%balance would be paid before shipment.

3. Q: How long is your delivery time?

A: 35 days upon receipt of advanced payment.

4. Q: lt is possible to get samples from your factory?

A: Yes. free samples will be provided.

5. Q: How many years the products guaranteed?

A: Minimum 1 years.